PRAGUE, CZECH REPUBLIC, July 29, 2019: Entrance Of Shop Michael Kors Store On Prague Airport. Michael Kors Is USA Shop For Luxury Designer Handbags, Watches, Shoes And Clothing Stock Photo, Picture And

Michael Kors | Jewelry | Michael Kors Sparkling Czech Crystal Open Hoop Drop Stud Earrings Rose Gold Nwt | Poshmark

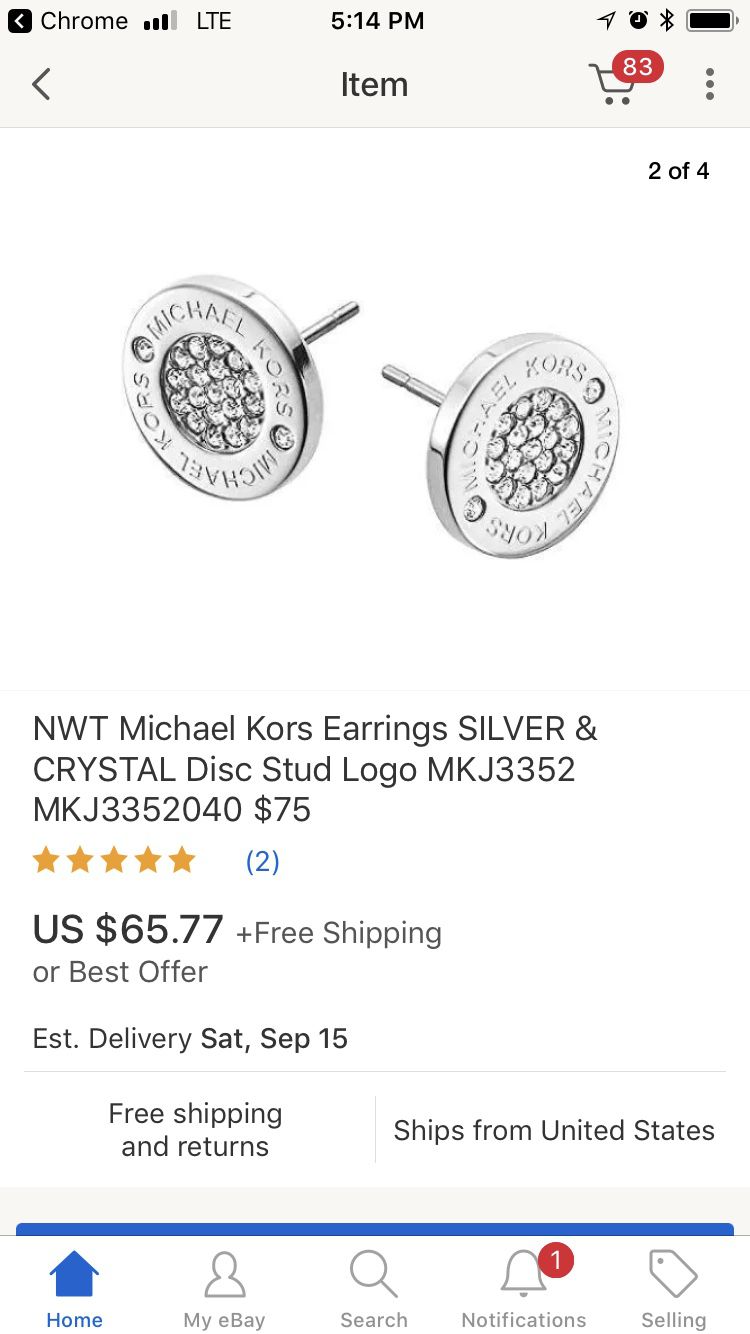

Michael Kors MKJ3352 Silver Tone MK Logo Plaque Stud Earrings w Czech Crystals. New for Sale in Phoenix, AZ - OfferUp